|

Product Details:

|

| Condition: | New | Weight: | Depend On Design |

|---|---|---|---|

| Voltage: | 380V 50Hz 3phases | After-sales Service Provided: | Engineers Available To Service Machinery Overseas |

| Ile Type: | Colored Glaze Steel | Control System: | PLC(imported Brand) |

| High Light: | cold roll forming machine,profile roll forming machine |

||

1. Description

1. The structure is simple and the appearance of the gutter machine is beautiful.

2. Gutter roll forming machine adopt the shape-steel structure and process as a whole after welding. It has

the ability of strong loading and stable operation when running the machine.

3. All the components of machine are from brand-famous enterprise so that they ensure the machine normal function very effectively.

4. It is very easy to install the equipment and suitable for producing in the factory.

5. The machine has features of low noise and high efficiency.

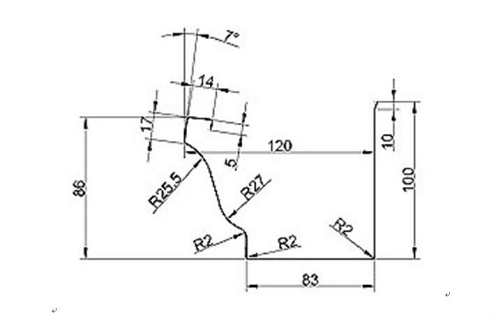

2. Gutter Sketch

3. Process

4. Technical Details

| Machine Specifications | |

| Weight | About 7000kgs |

| Size | About 12m x 1.1m x 1.2m (length x width x height) |

| Color | Main color: blue |

| Warning color: yellow | |

| Suitable Raw Material | |

| Material | PPGI and PPGL Coils, Copper |

| Thickness | 0.5-0.7mm |

| Coil width | 610mm |

| Yield Strength | 235Mpa |

| Main Technical Parameters | |

| Diameter of forming rollers shafts | 55mm |

| Quantity of roller stations | 25 rows |

| Roll Forming Speed | About 20m/min |

| Forming rollers material | No.45 steel, coated with chromed treatment |

| Cutter material | CR12 mould steel, with quenched treatment |

| Controlling system | PLC and Converter |

| Electric Power requirement | Main motor power: 5.5kw |

| Hydraulic unit motor power: 5.5kw | |

| Electric voltage | According to customer’s requirement |

5. Main Components

| No | Name | Quantity | Remarks | |

| 1 | Decoiler | 1set | Up to customer | |

| 2 | Main machine | Pre-cutting device | 1set | Up to customer |

| Feeding device | 1set | |||

| Roll forming system | 1set | |||

| Post cutting device | 1set | |||

| Hydraulic system | 1set | |||

| 3 | Electric control system | 1set | ||

| 4 | Supporter/Automatic Stacker | 1set | Up to customer | |

6. Application

machine picture

Contact Person: Arno Hao

Tel: +8618717894416