Automatic Roll Forming Machine To Make Cable Tray Roll Forming Machine

Decoiler------guiding------leveling---punching-------roll forming--------cut to length-----output table

De-coiler------------------------------------------1set

Forming machine--------------------------------1set

Cutting device -----------------------------------1set

PLC control box ---------------------------------1set

Hydraulic pump station-------------------------1set

output table-----------------------1set

1)Cable Tray Roll Forming Machine Manufacturing Supplier Decoiler

Decoiler

| Width |

500mm |

| Inner Diameter |

508mm |

| Outter Diameter |

3000mm |

| Capacity |

5000kg |

| Type |

Manual Or Hydraulic

|

| 1 |

Material thickness |

1mm-2mm |

| 2 |

Feeding width |

300-700mm |

| 3 |

Effective width |

100-600mm |

| 4 |

Forming Steps |

22steps |

| 5 |

Line Speed |

8 to 12m/min(adjustable) |

| 6 |

Stand |

Independent stand structure (raft structure) |

| 7 |

Drive |

Independent motor and moved by chain |

| 8 |

Material of Roller |

40Cr, HRC45-55 |

| 9 |

Shaft Diameter |

80mm |

| 10 |

Main Motor Power |

About 30KW |

| 11 |

Voltage |

380V/50HZ/Three Phase |

|

NO.

|

Name

|

QTY

|

Remark

|

|

1

|

5T hydraulic decoiler

|

1 set

|

1)Max 5T

2)Max coil:1000mm

3)Hydraulic inner expansion and motorized decoiling

|

|

2

|

Guiding,feeding Leveling

|

1 set

|

1)2 pinch rolls and 7 rolls leveling

2)Rolls material:40Cr

3)Leveling speed:max 20m/min

|

|

3

|

Servo-feeder system

|

|

1)Feeding speed:max 20m/min

2)Motor:1.8kw plus reducer

|

|

4

|

250T Punching press

|

1 set

|

1)Motor:15KW

2)Slide stroke:max 60 times /min

|

|

5

|

100-600mm Width holes punching&cutting mould

|

1 set

|

1)Mould material Cr12Mov

2)Combination mould to punch from 100mm to 600mm

3)Qty: 1 set

4)The punching heads will be controlled by air cylinders to punch rectangular holes and oval-shaped holes according to actual

production size.

|

|

6

|

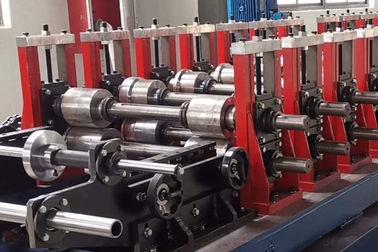

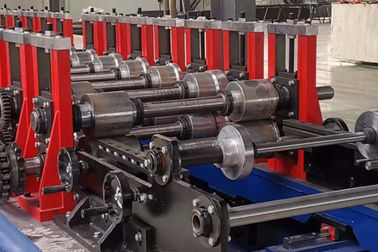

Roll forming Machine

|

|

1)Cantilever type welded structure

2) 14 forming stations plus 4 vertical rolls

3)15KW motor made in China

4) Automatic size adjustment controlled by PLC

5) 1.2inch chain drive

6) Rolling speed:max 15m/min

|

|

7

|

Hydraulic post-cutting system

|

1 set

|

1) We adopt hydraulic post mould cutting

2) Cutting power:7.5kw

3) A set of cutting blade to cut from 100mm to 600mm

|

|

8

|

Run-out table

|

2pcs

|

Steel frame with Rollers

|

|

9

|

Electric panel

|

1set

|

PLC control system made in Japan

|

|

10

|

Hydraulic system

|

1 set

|

Solenoid is from chinese famous brand

|

Packing Detall

| (1) |

40 GP container ; main machine naked and fastened with iron wire in the container. |

| (2) |

rollers were painted with oil and packed with plastic film. |

| (3) |

electrics devices be packed with wooden box |

| (4) |

All Components Fixed by steel wire with Container.

|

Our service

Re-sale Service :

1. Send you invitation letter, if you wanna visit our factory and check the machines.

2. Good Quality + Competitive price + Quick Response + Reliable Service.

Selling Service :

1. Email the production schedule and make prompt delivery.

2. Count the cheapest shipping cost, look for the fastest forwarder and send relevant documents promptly.

3. Be here for your service at any time.

After-sale Service :

Any questions, contact us by whatsapp or Telephone.

WHY CHOOES CHBEST COMPANY

1) Q: Do you have after sales support?

A: Yes, we are happy to give advice and we also have skilled technicians available across the world. We need your machines running in order to keep your business running.

2)Q: How do your machines compare with other big companies in this market?

A: We are up to date with the latest technology and improve our machines accordingly

3) Q: Will you deliver the right goods as ordered? How can I trust you?

A: Yes, we will. The core of our company culture is honesty and credit. Best is ALIBAB’s Gold supplier with BV assessment and CE certificate.

cable machinery advantages:

1. High standard quality, key eletric components are original international brand.

2. BEST is a strong company power to ensure you can find us for support at any time.

3. We do not only produce cable production line machine, but also produce fiber cable to helps ourself to insist on improving our machine in time.

4. We have rich experience over 20 years machine and cable manufacture, enough training technicians.

5. We have a large professional teams for pre-sales and after sales services.

6. After sales service for free spare parts, online support, field installation, commissioning and training, field maintenance and repair service, vedio technical support.

7. Advanced technology applied to our machine with the times.

8. Support with cable raw material information and cable production technology.

9. ISO9001, ISO14001, OHSAS18001 certified, CE certified support.

10. Techical Datasheets, Machine Inventment Evaluation, OEM support.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!