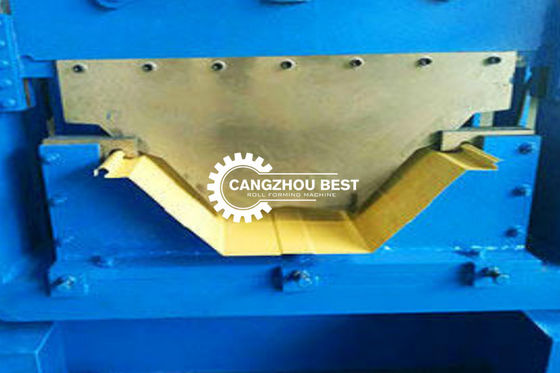

K span roof roll forming machine - NT600 with Curving machine and biting machine

K Span roof roll forming machine line consists of k span roof roll former, k span curving machine and k span biting machine. The whole line is used to make K span roofing system.

Forming Machine consists of one main roll former, one curving/bending machne and one biting machine. Roll Forming Machine for K Span System. K-Span is high quality Pre-Painted Galvanized Steel Roofing, combining low prices with fast erection. KSPAN Building Systems refer to the first generation of Automatic Building Machines that can be used for Industrial, Agricultural, Housing, Institutional, Recreational or Commercial Building Needs.

K-Span Building System offers excellent Institutional Buildings in an Economical manner . K-SPAN Building System is suitable for Farm, Barns, Vegetable Stores and Storage silos. The System can be used to create sheds to protect your vehicles. Aircraft Hangers can be created using the system. Moreover, low cost residential units can be erected in a quick manner

1. Main Parameter:

1.Material to be rolled: Q235, Colorbond or galvanized Steel, coil

2.Thickness of the material0.8-1.3 mm

3.Coil width max: 914mm

4.Inner diameter of the coil: 520mm, subject to buyer’s requirement

5.Outer diameter of the coil: 1800mm

6.Decoiler: 5000kg, manual expansion

7.Roll stands: 19

8.Main structure: wall style entire steel structure

9.Driving system: chain transmission

10.Main power: 5.5KW

11.Main reducer: cycloid pin

12.Cutting: Hydraulic cutting

13.Power of hydraulic station: 3KW

14.Material of blade: Cr12, heat treated HRC58-62

15.Measure: encoder

16.Controller: PLC

17.Forming speed: about 5-15m/min

18.Dimensionabt. 13m*1.3m*1.5m

19.Weight: abt.13mt

20.biting machine

21.bending machine (if necessary)

Process:

Manual decoiler——guiding——roll forming——hydraulic cutting——run out table

Features of our k-span machine

1. This M/C adopts inner-expansion manual decoiler. The diameter can be adjusted through the adjusting bolt according to the coil’s inner diameter. The operation is quite easy. The decoiling speed is to the main machine’s forming speed.

2. The main frame is structured by welding entire T shape steel. The side stands are welded on the frame, and to clear the stress by vibration in order to maintain the rigidity and stability of the machine.

3. The forming rollers are made of GCr15 bearing steel through a series of heat treatment such as forging, distressing anneal, high frequency hardening(the degreed is 8-10mm), backfiring, phosphorization etc. The surface of the rollers can reach the rigidity of HRC58-62. All the forming rollers are process on CNC lathe, by which the accuracy can be granteed.

4. The main shaft is made of 40Cr advanced alloy steel after a series of heat treatment such as high frequency hardening, quenching and tempering etc and processed on lathe, burnishing the surface, wire cutting the channel to make it high accuracy and large capacity.

5. Cut to length is the last process of this machine line. It cuts accurately to any length you set on the PLC. The cutter consists of Hydraulic diver, profiled blade and cutter frame. The blade is made from Cr12 cold punching steel after strict process. It adopts 45 degree staggering cutting. This costs no waste and can hold the cutting profile a good shape. And this cutting is of high accuracy.

6. The machine adopts Panasonic series industrial PLC, Panasonic VF series Transducer and Omron encoder. The entire electric components are in world brand name and of good stability and long life.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!