Product Description:

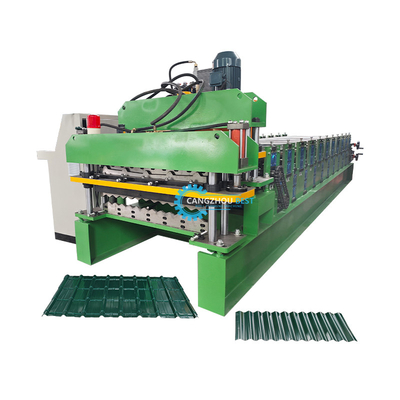

The Double Layer Roof Panel Roll Forming Machine is capable of handling a material thickness range of 0.25-0.6mm, making it suitable for a wide range of roofing panel applications. The width of the panels can be customized according to the needs of the user, giving them complete control over the final product.

This machine comes equipped with 15 stations and 16 stations, which means it can produce two different types of roofing panels simultaneously. This feature saves time and increases efficiency, making it an excellent choice for large-scale industrial applications.

One of the most significant advantages of our Double Layer Roll Forming Machine is its automatic operation. The machine's advanced control system ensures that the roll forming process is carried out smoothly and seamlessly without the need for constant supervision. This feature not only saves time but also reduces the risk of errors and accidents.

The Double Layer Roof Panel Roll Forming Machine has a roll forming speed of 15-20m/min, making it one of the fastest machines in its class. This high-speed production capability means that users can produce a large volume of roofing panels in a short amount of time, further increasing productivity.

In conclusion, the Double Layer Roll Forming Machine is a versatile and efficient solution for all your roofing panel needs. Its automatic operation, high-speed production, and ability to produce two different types of panels simultaneously make it an excellent investment for any industrial facility. Contact us today to learn more about this remarkable machine and how it can benefit your business.

Features:

- Product Name: Double Layer Roll Forming Machine

- Main Motor Power: 5.5Kw

- Raw Material: PPGI

- Width: Cutomized

- Forming_Speed: 8-12m/min

- Roller Stations: 15 Stations +16 Stations

This product is a double layer roof panel roll forming machine, also known as a steel profile roofing sheet roll forming machine or color steel roofing sheet double layer roll fomring machine.

Technical Parameters:

| Product Name |

Double Layer Roofing Sheet Roll Forming Machine |

| Roll Forming Speed |

15-20m/min |

| Machine Size |

7.6*1.4*1.5m |

| Advantage |

Automatic Operation |

| Width |

Customized |

| Material Thickness |

0.25-0.6mm |

| Export Port |

Tianjin Port |

| Roller Material |

High Grade 45# Steel |

| Forming Speed |

8-12m/min |

| Roller Stations |

15 Stations + 16 Stations |

| Inverter Brand |

Delta |

Applications:

This double layer roll forming machine is perfect for metal roofing manufacturers, contractors, and builders. It can be used in various occasions and scenarios, such as:

- Residential roofing projects: This machine is ideal for producing roofing sheets for residential buildings. It can create durable and reliable roofing panels that can withstand harsh weather conditions.

- Commercial roofing projects: The double layer roll forming machine is also suitable for producing roofing panels for commercial buildings. It can create panels in various sizes and shapes to fit the needs of different commercial structures.

- Industrial roofing projects: This machine is also perfect for producing roofing panels for industrial buildings. It can create strong and durable panels that can withstand heavy loads and harsh environments.

The BEST Double Layer Roll Forming Machine is made of high-quality materials and is designed to handle PPGI raw materials. It is also equipped with a variety of safety features to ensure that the production process is safe and efficient. The machine can be exported through Tianjin Port, making it accessible to customers all over the world.

In summary, the BEST Double Layer Roll Forming Machine is an excellent investment for anyone who needs a reliable and efficient machine for producing double layer roof sheet and color steel roofing sheet. Whether you are a metal roofing manufacturer, contractor, or builder, this machine can help you produce high-quality roofing panels in a variety of sizes and shapes. With its automatic operation and high forming speed, it is a great choice for any roofing project.

Customization:

Support and Services:

The Double Layer Roll Forming Machine is designed to efficiently produce two different profiles of metal sheets with a single machine. Our technical support and services for this product include:

- Installation and commissioning of the machine at the customer's site

- Training of customer's personnel on machine operation and maintenance

- Regular maintenance and service checks to ensure optimal machine performance

- 24/7 technical support for trouble-shooting and problem-solving

- Supply of spare parts and accessories for the machine

- Upgrade and retrofit services to enhance machine capabilities and functionality

Our team of experienced technicians and engineers are dedicated to providing the best technical support and services to our customers to ensure maximum productivity and efficiency of the Double Layer Roll Forming Machine.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!