Product Description:

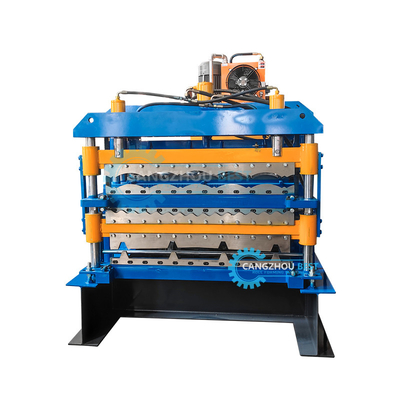

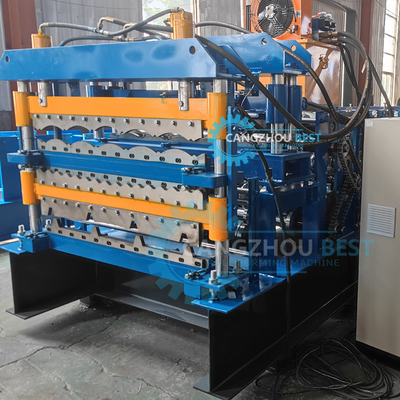

The Three Layer Roll Forming Machine is a versatile and efficient machine designed for producing high-quality triple layer roof sheets. With a pitch of wave measuring 76mm (±2.0mm) and a depth of wave at 18mm (±1.5mm), this machine is capable of creating precise and uniform waves on the roofing sheets it produces.

Equipped with a shaft diameter of Φ70mm, the Three Layer Roll Forming Machine ensures stability and durability during the roll forming process. The machine's Type YX1085 design is specifically optimized for producing three layer roof sheets with utmost precision and efficiency.

One of the key features of the Three Layer Roll Forming Machine is its impressive output capacity. With the ability to produce 2-4 tons of triple layer roof sheets per hour, this machine is ideal for high-volume production requirements.

Whether you are in the construction industry or involved in roofing sheet manufacturing, the Three Layer Roll Forming Machine offers a reliable and cost-effective solution for your production needs. Its robust construction and advanced technology make it a valuable asset for businesses looking to enhance their production capabilities.

By investing in the Three Layer Roll Forming Machine, you can benefit from increased efficiency, reduced production time, and consistent quality in every triple layer roof sheet produced. The machine's precise control system allows for easy operation and adjustment, ensuring that you can achieve the desired wave pitch and depth with accuracy.

Overall, the Three Layer Roll Forming Machine is a top-of-the-line equipment that delivers exceptional performance and reliability in the production of three layer roof sheets. Its innovative design, high output capacity, and precise wave formation capabilities make it a must-have machine for businesses seeking to optimize their production processes and meet the growing demand for quality roofing materials.

Features:

- Product Name: Three Layer Roll Forming Machine

- Rolling Thickness: 0.3mm-0.8mm

- Equipment Weight: 10 tons

- After-sales Service Provided: Engineers Available To Service Machinery Overseas

- Product Category: Double Layer Roll Forming Machine

- MATERIAL TO BE CORRUGATED: FULL HARD GALVANIZED SHEETS

Technical Parameters:

| PITCH OF WAVE |

76MM (±2.0MM) |

| THICKNESS RANGE OF SHEET |

0.3 MM TO 0.8 MM |

| Product Category |

Double Layer Roll Forming Machine |

| Voltage |

380V 50Hz 3phases |

| Product Name |

Three Layer Corrugated& Roof Tile&Trapezodial Roof Sheet Roll Forming Machine |

| OUTPUT |

2-4 TONS PER HOUR |

| Equipment Weight |

10 tons |

| After-sales Service Provided |

Engineers Available To Service Machinery Overseas |

| Rolling Thickness |

0.3mm-0.8mm |

| DEPTH OF WAVE |

18MM(±1.5MM) |

Applications:

The CHBEST Three Layer Roll Forming Machine, model number XY1085, is a high-quality machine suitable for various product application occasions and scenarios. This machine is widely used for producing triple layer roof sheets, providing a durable and efficient solution for roofing needs.

With certifications including CE, BV, and SGS, you can trust the reliability and safety of this machine. Originating from China Hebei, this machine is manufactured with precision and expertise.

The CHBEST Three Layer Roll Forming Machine has a minimum order quantity of 1 set and a supply ability of 20 sets per month. The delivery time for this machine is 20-30 days, ensuring prompt availability for your production needs.

When it comes to packaging, this machine is carefully protected with plastic film for the naked machine, ensuring that it arrives in perfect condition at your facility.

Constructed with roller material made of 45 # forge steel, this machine is built to last and withstand the rigors of continuous operation. The depth of wave produced by this machine is 18mm (±1.5mm), creating sturdy and reliable roof sheets.

The output of the CHBEST ThreeLayer Roll Forming Machine is impressive, with the capability to produce 2-4 tons per hour. This high efficiency makes it ideal for large-scale production requirements.

Designed for full hard galvanized sheets, this machine can handle a thickness range of sheet material from 0.3mm to 0.8mm. This versatility allows for flexibility in the types of materials that can be corrugated using this machine.

Whether you are in need of a triple layer roof sheet machine, three layer roof sheet machine, or any other similar application, the CHBEST Three Layer Roll Forming Machine is a reliable and efficient choice for your production needs.

Support and Services:

The Three Layer Roll Forming Machine is a versatile piece of equipment designed for efficiently producing double layers of roofing sheets or wall panels. Our product technical support team is dedicated to providing comprehensive assistance with installation, operation, and maintenance of the machine.

We offer a range of services to ensure the optimal performance of the Three Layer Roll Forming Machine, including regular maintenance checks, troubleshooting support, and technical training programs for operators.

Our team of skilled technicians is available to address any technical issues that may arise and provide timely solutions to minimize downtime and maximize productivity.

Packing and Shipping:

Product Packaging:

The Three Layer Roll Forming Machine will be securely packaged in a durable wooden crate to ensure safe transportation and delivery.

Shipping:

We offer worldwide shipping for theThree Layer Roll Forming Machine. Once the order is confirmed, the product will be carefully packed and shipped within 5-7 business days. Customers will receive a tracking number to monitor the delivery status.

FAQ:

Q: What is the brand name of this Three Layer Roll Forming Machine?

A: The brand name is CHBEST.

Q: What is the model number of this Three Layer Roll Forming Machine?

A: The model number is XY18085

Q: What certifications does this Three Layer Roll Forming Machine have?

A: It is certified with CE/BV/SGS.

Q: Where is this Three Layer Roll Forming Machine manufactured?

A: It is manufactured in China Hebei.

Q: What is the minimum order quantity for this Three Layer Roll Forming Machine?

A: The minimum order quantity is 1 set.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!