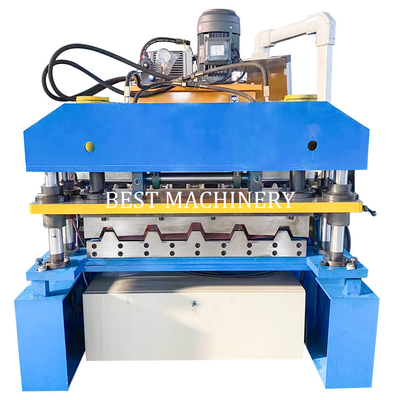

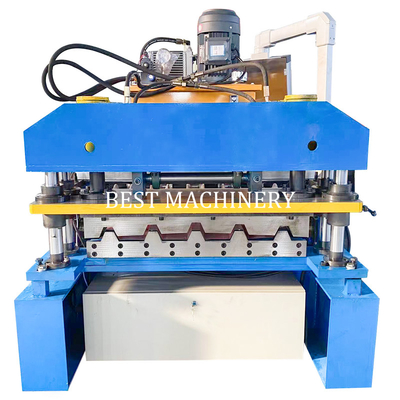

High Precision Color Steel South Africa YX686 Roof Sheet Roll Forming Machine

Working Process:

Decoiler -- Feeding & Guiding -- Roll forming--Hydraulic pressing --Hydraulic Cutting - Product to run out table

Specifications

| FEEDING |

Guide Pillar |

45# Steel Precision,Smoothly |

| Pre cutter |

Fully automatic Pre cutter to save your material |

|

ROLL MACHINE

|

Frame Structure |

350H-beam welded and stand wall |

| Sidewall |

Use 45mm separate station box |

| Screw/Bar |

8.8 grade / 25mm Galvanized |

| Roller Station |

According to customer requirements |

| Roller Shaft |

75mm 45# Steel Solid,Precision |

| Shaft Material |

45# Steel Solid,Precision |

| Roller Info. |

45# steel harden chromed plated |

| Transmission |

Chain 1 inch |

| Motor Power |

5.5(Lichao,Shanghai) |

| Output Speed |

About 10-15m/min |

|

CUTTING

|

Frame Structure |

350mmCarbon Steel |

| Cutting Type |

Hydraulic Automatic |

| Cut Performance |

No scrap,no deformation |

| Cutting Blade |

Cr12Mov,hardness 60-62℃ |

|

HYDRAULIC

SYSTEM

|

Installation |

inside,easy for operation |

| Pump Motor |

3.0KW(Lichao,Shanghai) |

|

COMPUTER

SYSTEM

|

Electrical Control |

DELTA PLC TAIWAN

DELAT Inverter TAIWAN

|

| Length Control |

Rotaty Encoder from Omron |

|

Length Tolerance

|

±1.5mm |

| Touch Screen |

DELTA(TAIWAN) |

|

Low Voltage Components

|

Limit Switch/Contactor/Relay

|

| VOLTAGE |

According to customer |

Details:

Rollers are being CNC tooling so that can ensure the final product precision.

Rollers material are high grade No.45 forged steel plated with 0.05mm hard chrome.

Shafts are tooled by grinding machine two times to ennsure product accuracy.

Shafts material are NO.45 forged steel with diameter of 72mm,strong and durable.

Make the machine frame smooth with planer milling machine so that the wall plate can be installed with high accuracy.

Automatic operation

Use Mitsubishi PLC with touch screen. Friendly man-machine interaction.

The system is simple to learn and easy to operate.

Installation and Training:

① If buyers visit our factory and check the machine, we will teach you how to install and use the machine, and also train your workers/technician face to face.

② Without visiting, we will send you user manual and video to teach you to install and operate.

③If buyer needs our technician to go to your local factory,please arrange round trip tickets, food and hotel and everyday salary USD100, visa cost and necessary things.

FAQ

1.Does one roll forming machine can only produce one size?

A.Not exactly, it depends on the machine.

2.Do you have after sales support?

A.Yes, we are happy to give advice and also have skilled technicians available to maintain the machine if needed.

3.What can you do if the roll forming machine broken?

A.Wow roll forming machine's warranty period is 18months. if the broken parts can't repair, we can send the new parts replace the broken parts,but you need pay the express cost by yourself. if after warranty period, we can through negotiation for solving the problems, and we supply the technical support for the whole life of the equipment.

4.Can you be responsible for transport?

A.Yes, please tell us the destination port or address. we have rich experience in transport.

5.You are trade company or factory?

A.We are Manufacturer.

6.Do you provide customized?

A.Sure, we can design the equipment according to the data of the structural section you provide. We are professional sheet metal forming machine designer and manufacturer.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!