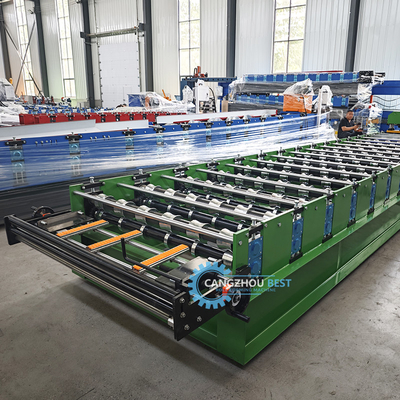

Product Description:

The roofing sheet roll forming machine is designed to operate on a power supply of 380V/3Phase/50Hz. It has a main motor power of 5.5Kw, which provides enough power to drive the machine and produce high-quality roofing sheets. The machine is also designed to handle material thickness ranging from 0.3-0.8mm, making it ideal for producing a wide range of roofing sheets.

The hydraulic station power of the roofing sheet roll forming machine is 3Kw. This ensures that the machine operates smoothly and produces high-quality roofing sheets. Additionally, the machine is designed to cut with a tolerance of ±2mm, which ensures that the final product is accurate and meets the required standards.

Whether you are looking to produce high-rib roof sheets, ibr roof sheets, or corrugated roof sheets, our roofing sheet roll forming machine is the perfect equipment for you. It is designed to produce high-quality and accurate roofing sheets that meet the required industry standards.

Invest in our roofing sheet roll forming machine today and take your roofing sheet production to the next level. With its advanced features and high-quality output, you can be sure that you are making a wise investment for your business.

Features:

- Product Name: Roofing Sheet Roll Forming Machine

- Roller Material: 45# Steel

- Control System: PLC Control System

- Warranty: 1 Year

- Cutting Tolerance: ±2mm

- Material Thickness: 0.3-0.8mm

This high rib roof sheet machine is a top-quality forming machine for producing durable roofing sheets. It is designed with precision roller material made of 45# steel for maximum strength and durability. The PLC control system ensures the machine is easy to operate, while the 1-year warranty guarantees it will deliver reliable results. With a cutting tolerance of ±2mm and the ability to process material thicknesses of 0.3-0.8mm, this roof sheet roll forming machine is the perfect choice for any roofing project.

Technical Parameters:

| Product Name: |

Roofing Sheet Roll Forming Machine |

| Power Supply: |

380V/3Phase/50Hz |

| Main Motor Power: |

5.5Kw |

| Hydraulic Station Power: |

3Kw |

| Roller Material: |

45# Steel |

| Forming Speed: |

8-15m/min |

| Cutting Tolerance: |

±2mm |

| Cutting Length: |

Any Length |

| Control System: |

PLC Control System |

| Warranty: |

1 Year |

Applications:

The machine is designed to produce IBR roof sheet, which is a popular choice for roofing and wall cladding. The forming speed is between 8-15m/min, meaning that it can produce large quantities of sheets within a short time. The machine is suitable for use in various industries such as construction, engineering, and manufacturing.

The roofing sheet roll forming machine is designed to meet the needs of different customers. The cutting length is adjustable to any length, making it suitable for producing sheets of different sizes. The cutting type is hydraulic cutting, which is precise and efficient. This ensures that the sheets produced have neat edges and are of high quality.

The roofing sheet roll forming machine is easy to operate and maintain. It comes with a user-friendly interface that enables the operator to control the machine easily. The machine is also durable and requires minimal maintenance.

The roofing sheet roll forming machine is suitable for use in various applications, including commercial buildings, residential buildings, warehouses, and factories. It is also suitable for use in the construction of shopping malls, airports, and hospitals.

In conclusion, the BEST YX1000 roofing sheet roll forming machine is an essential tool for anyone involved in the production of metal sheets used for roofing and wall cladding. It is efficient, durable, and easy to maintain. It is suitable for use in various industries and can produce high-quality sheets within a short time.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!