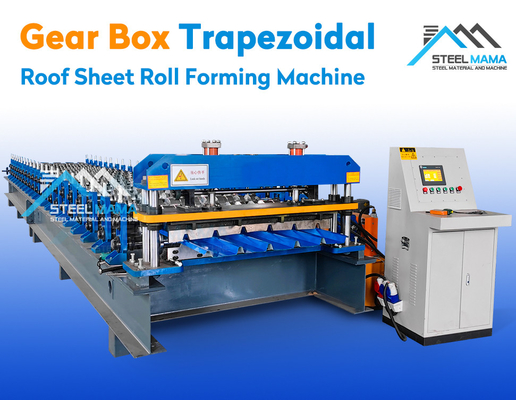

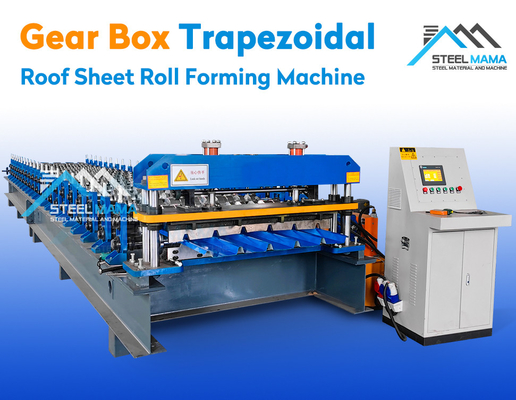

Product Description:

The machine is equipped with a hydraulic cutting system that ensures precise and efficient cutting of the roofing sheets. The cutting type used is hydraulic cutting, which ensures that the machine delivers high-quality products with accurate measurements and minimal wastage.

The Roofing Sheet Roll Forming Machine is designed to operate on a power supply of 380V/3Phase/50Hz. This ensures that the machine can be used in different regions, making it a versatile option for businesses that operate in various locations.

The machine is easy to operate, and its user-friendly design makes it an ideal option for businesses that are new to the roofing sheet production industry. The machine is also designed to be durable and long-lasting, ensuring that businesses can get a good return on investment.

Overall, the Roofing Sheet Roll Forming Machine is an excellent option for businesses that are looking to produce high-quality roofing sheets efficiently and effectively. Its versatile design, user-friendly operation, and efficient cutting system make it a reliable option for businesses of all sizes.

Features:

- Product Name: Roofing Sheet Roll Forming Machine

- Control System: PLC Control System

- Roller Material: 45# Steel

- Power Supply: 380V/3Phase/50Hz

- Cutting Tolerance: ±2mm

- Keywords: ibr roof sheet machine, cold roll forming machine, ibr roof sheet machine

Technical Parameters:

| Product Name: |

Roofing Sheet Roll Forming Machine |

| Power Supply: |

380V/3Phase/50Hz |

| Hydraulic Station Power: |

3Kw |

| Cutting Length: |

Any Length |

| Control System: |

PLC Control System |

| Main Motor Power: |

5.5Kw |

| Cutting Tolerance: |

±2mm |

| Forming Speed: |

8-15m/min |

| Warranty: |

1 Year |

| Cutting Type: |

Hydraulic Cutting |

Applications:

The main motor power is 5.5Kw, and the hydraulic station power is 3Kw, making this machine an efficient and reliable choice for those in the industry. The warranty on the machine is 1 year, giving you peace of mind when purchasing. The forming speed of this machine ranges from 8-15m/min, and the roller material is made from 45# steel, ensuring durability and long-lasting use.

This high rib roof sheet machine is perfect for a wide range of application occasions and scenarios. For example, it is ideal for use in the construction industry, allowing you to create high-quality roofing sheets for various projects. It is also an excellent choice for those in the manufacturing industry, as it can help you create custom roofing sheets for a wide range of applications.

Overall, the BEST steel roof sheet roll forming machine is a reliable and efficient choice for those in the industry. Whether you need to create custom roofing sheets for construction projects or manufacturing applications, this forming machine is sure to meet your needs. With its high-quality construction, excellent performance, and reliable warranty, you can trust that this machine will provide you with the results you need.

Customization:

Product Name: Roofing Sheet Roll Forming Machine

Brand Name: BEST

Model Number: TR4 TR5 R101

Place of Origin: CHINA

Certification: CE

Minimum Order Quantity: 1

Price: 8500-35000

Delivery Time: 35 days

Payment Terms: T/T, LC

Cutting Length: Any Length

Cutting Type: Hydraulic Cutting

Forming Speed: 8-15m/min

Roller Material: 45# Steel

This steel roof sheet roll forming machine is designed to efficiently produce high quality roof sheets. It is a versatile forming machine that can produce different types of roof sheets with ease. With hydraulic cutting and a forming speed of 8-15m/min, this machine can be used for both small and large scale production. The roll forming machine is made of 45# steel, ensuring high durability and long-lasting performance.

Support and Services:

The Roofing Sheet Roll Forming Machine is a complex piece of equipment that requires technical support and services to operate effectively. Our team of experts is available to provide you with the following:

- Installation and setup services

- Training and education on how to operate the machine

- Troubleshooting and technical support for any issues that arise

- Regular maintenance and repair services to keep the machine operating at peak performance

We understand that downtime can be costly, which is why we offer fast and reliable support to ensure your machine is back up and running as quickly as possible. Our goal is to help you get the most out of your investment in the Roofing Sheet Roll Forming Machine.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!