Product Description:

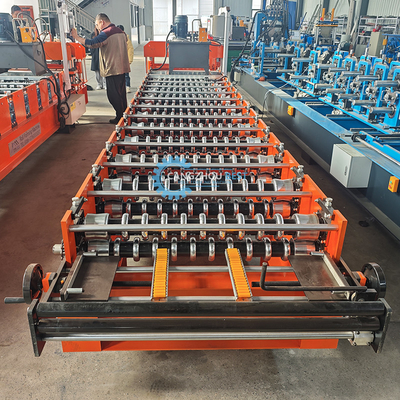

The machine features a PLC control system, which allows for easy operation and precise control over the production process. This ensures that each sheet produced is of consistent quality and meets the required specifications. Additionally, the machine is equipped with hydraulic cutting technology, which allows for accurate and efficient cutting of the sheets.

The Steel Profile Single Layer Roofing Sheet Machine is designed to be durable and reliable, with a 1 year warranty to give you peace of mind. It is also designed to be easy to maintain, with simple and accessible components that can be easily replaced or repaired if needed.

Overall, the Single Layer Roof Sheet Machine is an excellent choice for those looking for a reliable and efficient machine for producing high quality single layer roof sheets. Its advanced features and durable design make it ideal for use in a variety of roofing applications, and its ease of use and maintenance ensure that it can be operated with confidence by users of all skill levels.

Features:

- Product Name: Automatically Cutting Steel Roofing Roofing Sheet Rib Panel Roll Forming Machine

- Cutting Type: Hydraulic Cutting

- Hydraulic Station Power: 3Kw

- Warranty: 1 Year

- Features:

- Produces high rib roof sheets and other types of roof sheets

- Equipped with hydraulic cutting technology

Keywords: Single Layer Roof Sheet Machine, Single Layer Roof Sheet Machine, Single Layer Roof Sheet Machine

Technical Parameters:

| Technical Parameter |

Value |

| Product Category |

Steel Profile Single Layer Roofing Sheet Machine |

| Control System |

PLC Control System |

| Hydraulic Station Power |

3Kw |

| Cutting Type |

Hydraulic Cutting |

| Cutting Length |

Any Length |

| Cutting Tolerance |

±2mm |

| Power Supply |

380V/3Phase/50Hz |

| Main Motor Power |

5.5Kw |

| Roller Material |

45# Steel |

| Applications |

Residential, commercial, and industrial roofing projects |

Applications:

Our Roofing Sheet Roll Forming Machine is designed to help you create high-quality roofing sheets that are strong, durable, and long-lasting. It is the perfect product for anyone looking to create roofing sheets for their home, office, or any other building. The product is made of high-quality materials, and the hydraulic station power is 3Kw. The material thickness is 0.3-0.8mm, making it suitable for a wide range of roofing applications.

Our product is perfect for a variety of occasions and scenarios. Whether you are building a new home, renovating an existing building, or simply need to repair your roof, our Roofing Sheet Roll Forming Machine is the perfect product for you. The machine is designed to be easy to use, and it comes with all the necessary features and functions to help you create high-quality roofing sheets quickly and efficiently.

Our Roofing Sheet Roll Forming Machine is perfect for creating a range of roofing sheet types, including Single Layer Roof Sheet Machine, Single Layer Roof Sheet Machine, Steel Profile Single Layer Roofing Sheet Machine, and many more. The product is designed to be versatile and flexible, making it suitable for a wide range of applications.

Our product is suitable for use in a variety of industries, including construction, manufacturing, and roofing. It is the perfect product for anyone looking to create high-quality roofing sheets quickly and efficiently. With our Roofing Sheet Roll Forming Machine, you can create roofing sheets that are strong, durable, and long-lasting, ensuring that your building is protected from the elements for years to come.

Support and Services:

The Roofing Sheet Roll Forming Machine is a highly efficient and reliable piece of equipment designed for the production of high-quality roofing sheets. Our technical support and services team is dedicated to ensuring that your machine is always running smoothly and efficiently. We offer a range of services to help you maintain and optimize your machine's performance, including:

- Installation and commissioning

- Training and education

- Preventative maintenance

- Repair and replacement of parts

- Technical consultation and troubleshooting

- 24/7 customer support

Our team of experienced technicians is available to assist you with any questions or concerns you may have regarding your Roofing Sheet Roll Forming Machine. We are committed to providing you with the highest level of support and service to ensure that your machine is always operating at peak performance.

Packing and Shipping:

Product Packaging:

The roofing sheet roll forming machine will be packaged in a wooden crate to ensure safe delivery. The crate will be securely fastened and labeled with the product name and specifications.

Shipping:

Shipping will be arranged by the seller using a reliable carrier. The delivery time will depend on the destination and mode of transportation chosen by the buyer. The buyer will be responsible for any customs or import duties that may apply.

FAQ:

Q: What is the brand name of the roofing sheet roll forming machine?

A: The brand name of the roofing sheet roll forming machine is CHBEST.

Q: What is the model number of the roofing sheet roll forming machine?

A: The model number of the roofing sheet roll forming machine is XY24-210-1000.

Q: What certifications does the roofing sheet roll forming machine have?

A: The roofing sheet roll forming machine has CE/BV/SGS certifications.

Q: Where is the roofing sheet roll forming machine made?

A: The roofing sheet roll forming machine is made in China Hebei.

Q: What is the minimum order quantity for the roofing sheet roll forming machine?

A: The minimum order quantity for the roofing sheet roll forming machine is 1 set.

Q: What is the supply ability of the roofing sheet roll forming machine?

A: The supply ability of the roofing sheet roll forming machine is 20 sets/month.

Q: What is the delivery time for the roofing sheet roll forming machine?

A: The delivery time for the roofing sheet roll forming machine is 20-30 days.

Q: What are the packaging details for the roofing sheet roll forming machine?

A: The roofing sheet roll forming machine is packaged with plastic film for naked machine.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!