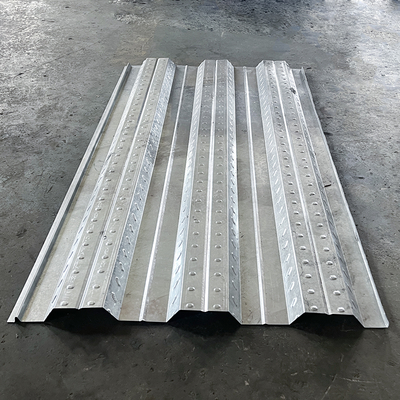

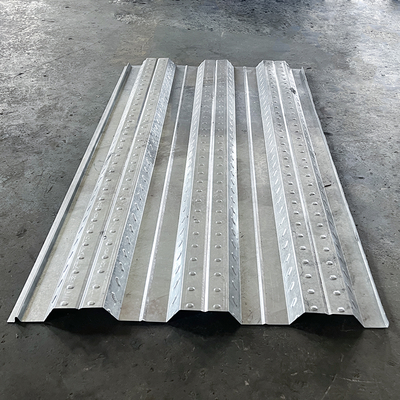

Metal Floor Decking Panel Cold Rollforming Production Line with Hydraulic Steel Cutting and Electric Rolling Machine

Technical Specifications

| Technical Items |

Details |

| Raw Material |

Type |

Steel Coils, Galvanised, Galvalume steel strips |

| Width |

It is up to the floor deck profile design |

| Thickness |

0.8-1.2 mm |

| Yield Strength |

235-345 MPa or specially designed for 550 MPa |

| Finished Rack Sheets |

Sizes |

It is up to the floor decking sheet profile designs |

| Length |

Adjustable |

| Motor Power |

Voltage |

220V/380V/415V/440V |

| Driving Motor |

11 KW x 2 |

| Cutting Motor |

5.5 KW |

| Production Speed of Roll Former |

around 10-15 meters per minute |

| Decoiler |

Type |

Manual or Electric Auto |

| Capacity |

3 tons or 5 tons |

| Rollforming Stations |

around 33 sets |

| Rolling Shaft Diameter |

82 mm |

| Rollers Material |

No. 45 coated with chrome |

| Punching Die |

Cr12 mould steel |

| Cutting Type |

With Post-cutting Device |

| Electric Control System |

Mitsubishi PLC, transducer and touching screen |

| Supporting Tables |

2 sets |

| Main Machine Size |

Around 16 x 1.6 x 1.6 meters |

| Equipment Weight |

Around 16 tons |

Working Process

Uncoiling---Sheet Guilding---Roll Forming---Cutting---Finished Floor Decks on Tables

ROLL FORMING MACHINE

(1)Material Thickness: 0.8-1.2mm

(2)Rollers: 26groups

(3)Material for Rollers: 45# steel polished and coated with chrome HRC55-60°

(4)Material for shaft: high grade No.45 steel after treatment

(5)Diameter of shaft: 90mm

(6)Frame panel thickness: 20mm

(7)Bottom frame: 35# H-section steel

(8)Motor Power: 2*11kw

(9)Driven type: 2.0"Chain

(10)Speed:8-12m/min

CUT-OFF DEVICE

(1)Material for Cut-Off Modular:Cr12 steel after treatment

(2)Hardness for Heat Treatment:HRC55 – 60°

(3)Cutt-Off Type: Hydraulic, Automatic Cut-Off

(4)Power:4kw

ELECTRONIC CONTROL SYSTEM

(1) Type: PLC Frequency Control System with touch screen

(2) PLC Brand: Delta

(3)Length Error: ±2mm

(4)Language: English and Chinese

(5)Voltage: 380v/50HZ, 3Phase

(it depends on customer requirement)

HYDRAULIC PUMP STATION

(1) Motor power: 4 kw

(2)Oil type: 46# hydraulic oil

(3) Pump brand: China brand

(4)Cooling fan

Installation and Training:

① If buyers visit our factory and check the machine, we will teach you how to install and use the machine, and also train your workers/technician face to face.

② Without visiting, we will send you user manual and video to teach you to install and operate.

③If buyer needs our technician to go to your local factory,please arrange round trip tickets, food and hotel and everyday salary USD200, visa cost and necessary things.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!