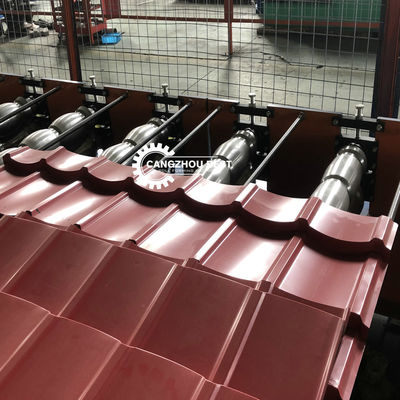

Corrugated Metal Profile Floor Tile Roof Roll Forming Making Machine For Construction Material

What is roof tile machine used?

Steel Profile Glazed Tile Roof Roll Forming Machine is widely used in the construction of various industrial plants, villages, warehouses, supermarkets, hotels, exhibition, family construction, shopping malls shutter doors and etc. It has the advantage of beautiful, classical appearance and grace taste.

Roof Tile Machine Specifications:

| No |

Item |

Description |

| 1 |

Coil |

Width: customized |

| 2 |

Forming speed |

8-15m/min&1-4m/min (not including cutting time) |

| 3 |

Roller Stations |

15&16stations |

| 4 |

Material of Roller |

45# steel finish machining, plated hard |

| 5 |

Material of Main Shaft |

45# steel finishing machining and then slack |

| 6 |

Material of Shaft |

80 mm 45#steel forged |

| 7 |

Driven Motor Power |

5.5KW |

| 8 |

Hydraulic Station Power |

3KW |

| 9 |

Hydraulic Station Pressure |

12.0 Mpa |

| 10 |

Electrical Control System |

Taida PLC |

| 11 |

Dimension (L*W*H) |

7300*1550*1200mm |

| 12 |

Material of Cutter |

GCr12 |

| 13 |

Driving Mode |

single chain 1 inch |

| 14 |

Material Thickness |

0.3-0.8mm |

| 15 |

Power Supply |

380V, 60HZ, 3 PHASES |

| 16 |

Cutting accuracy |

±2 mm |

Working flow:

Decoiler---Feeding&Guiding---Roll Forming---Hydraulic Pressing&Cutting---Receiving Table

Machine production:

|

1. Un-coiler: 5 tons passive

2. Insider diameter of the un-coiler: 450-550mm

|

|

1. Pressing and cutting way: Hydraulic cut.

2. Hydraulic power: 3kw hydraulic system.

3. Blade Material: CR12Mov with heat treatment HRC58-62.

|

|

1. Material Thickness: 0.3-0.8mm PPGI and GI

2. Material for Rollers: high grade 45# steel polished and coated with chrome HRC55-60°

3. Material for shaft: high grade 45# steel polished and coated with chrome HRC55-60°

|

1.Length & quantity controlled by PLC

Length inaccuracy can be amended easily.

2.Control panel: Button-type switch and touch screen

3.The language in the touch screen: English and Chinese

4.Unit of length: millimeter (switched on the control panel) |

|

1.Motor power: 3 kw

2.Oil type: 46# hydraulic oil

3.Pump brand: China brand

|

1.It adopts welded steel and supported roller to transmit the products.

|

Our service:

1.We can promise the tolerance to be 0.8mm due to 18 sets CNC machines on site. All the rollers and shafts are solid.

2.We have more engineers with more than 10 years experience to offer the most popular solutions.

3. installation engineers can go to your site within 7 days.

4.12 months maintenance and whole life technical support.

5.We cooperate with ,APL,CMA,EMC,MSC, and PIL etc, 32 big shipping companies.

1) Pre-sale Service

* Send you invitation letter, If you wanna visit our factory and check the machines.

* Good Quality Manufacturer competitive price Quick Response Reliable Service for you.

2)Selling Service

* Short delivery time after deposit 30-40 days.

* Email you the production schedule and make prompt delivery for you.

* We will count the cheapest shipping cost and fastest forwarder for you and send documents promptly.

* Always be here for your service 12 hours per day.

3) After-sale Service

* We welcome all feedback about our products and prices and services from our customers.

* Any questions, please contact with us freely by E-mail or Telephone

Cangzhou BEST Machinery CO., LTD, located in the beautiful coastal city-Cangzhou, is a high-tech enterprise and won several technology patents. AND Products mainly include trapezoidal steel roof/wall panel machine, C&Z shape purline machine, high-way guardrail machine, sandwich panel production line, deck forming machine, C U L light keel machine, shutter slat door forming machine, cutting machine, downpipe machine, gutter machine, etc. We are the ownership of cutting system(size adjustable,don't need to replace cutting mold), purlin size fast changing system(choose any size in range), coaxial C/Z interchanging system(CZ combined one machine) and many new type machines cradle. For many years, the company has focused on the research and develop of new tehnologies of CZ purlin equipment.As a result, it has initiated the application of fast cutting system and coaxial C/Z interchanging system and promoted a trend of upgrading of the whole CZ processing area. The company has developed single product to a category, thus creating a new model for successful operation of independent brand in rolled steel industry.

Machine Photos:

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!