|

Q1. Why do we choose BEST Machinery ?

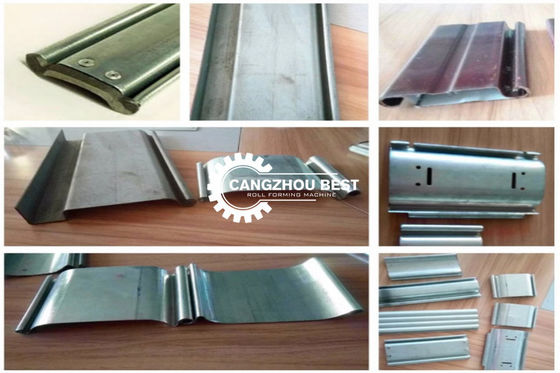

A1. We are professional manufacturer of various kinds of sheet metal forming

machine which located in Foshan city of Guangdong province, Which has

over 14 years experience for producing roll forming machine for door

frame, window rail support, storage racking, drawer slider, light steel keel,

U&C shaped pipe,highway guardrail and so on metal product. For these

products, . Not only have rich experience to produce high quality machine,

but also with strong technical team as basis.

Q2. ls there any quality warranty and after service ?

A2. The warranty of mechanical portion of the equipment shall be a year after

you received the equipment;And help buyer installation and commissioning

the equipment, and free training operator.�

Q3. If there any quality problem of your machine and spare parts, what

should I do?

A3. Within one years, if machine have any quality problem. we will repair for

free.But if damaged parts will be.replaced by offered of charge. we provide lifelong tracing service, supply equipment parts and relevant maintenance

at favorable prices, and give user technical guidance free of charge.

|

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!