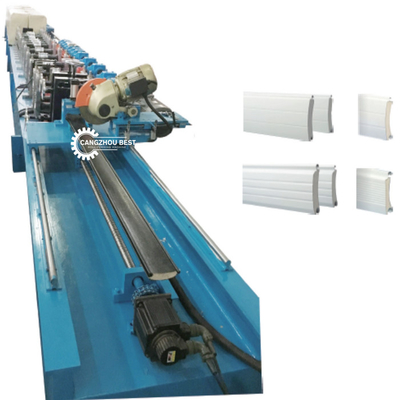

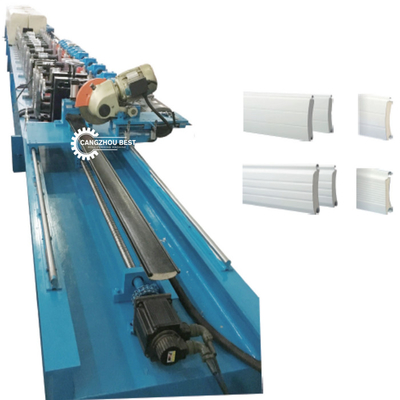

1.2mm 42/55/77 Metal PU Foam Roller Shutter Door Roll Forming Machine

Working Flow:

Decoiler-------roll forming--------foaming-------roll forming ------cut to length-----output table

Machine components:

De-coiler------------------------------------------1set

Forming machine--------------------------------1set

Foam device--------------------------------------1set

Flying saw----------------------------------------1set

PLC control box ---------------------------------1set

Production support table-----------------------1set

PU Foam Roller Shutter Door Roll Forming Machine price Technical Parameters:

| No. |

Type |

Specification |

|

1

|

Row Material

|

Type |

Colored steel plate, Galvanized board |

| Feeding width |

225mm or According to client’s requirement |

| Thickness |

0.3mm |

|

2

|

Main Body

|

Forming roller station |

38Stations |

| Diameter of shaft |

40mm |

| Shaft material |

High grade 45# steel |

| Roller material |

High grade 45# steel , hard treatment and polishing ( plated chrome on surface ) |

| Main body frame |

Whole set of square pipe |

| Frame thickenss |

14 mm |

| Working speed |

8-15 m/min |

| Size (L*W*H) |

About 6800*850*1310mm |

| Weight |

About 2.5 tons |

|

3

|

Power

|

Motor power |

5.5 kw |

| Hydraulic power |

1.5 kw |

| Voltage |

380V 50Hz 3phases or Customerization |

| Drving Way |

By Chain |

|

4

|

PLC Control System

|

Language |

English and Chinese |

| Brand Of PLC |

Delta brand ( Touch Screen ) |

| Operation |

Manual and Automatic ( Two Type ) |

| Transducer |

Delta brand |

|

5

|

Cutting Device

|

Cutting Type |

Fly saw cutting |

| Cutting Tolerance |

± 1mm |

1. the advantage of roller shutter door machine china

it has reasinable structure, beautiful appearance, with advantage of saving space, easy operate and especially welcomed by the costomer with limit area or site operation.

2. Main Parameter and specification of the roller shutter door machinery

We design each machine according to user requirement. Below techinical parameters can be adjusted if needed.

PU Foam slat shutter door roll forming machine china

1. Suitable to process:Color steel plate

2. Width of the plate:100-160mm

3. Rollers :18-22rows

4. Dimensions: 22.0*0.8*1.2m

5. power:5.5kw

6. Thickness of the plate;0.6-1.2MM

7. productivity:8-12M/MIN

8. Dimension of the rolelr:Φ42mm

foaming roller shutter door:

1. Appearance and delicate: is made of high qualified steel plate (aluminum) rolling forming, not filled

with middle carbon fluorinated compounds of polyurethane foaming materials, heat insulation, sound insulation,

heat preservation.

2. Use fast: in the process of start, very swift and no noise, if use motor drive, power changed hands move

way can be met.

3. Durable: using high quality materials, sophisticated production technology and production technology,

meet slight collision after can sprung automatically deformation.

4. Save a space: the closed beta guide drive, promoting a door with other than to save the building, the internal

space, installation is more convenient.

Before ordering:

We can help to analyze the roof tile in your market. Which one is popular and which one will be popular.

Then your product is hot sale roof tile .

We can confirm all details of the roof tile roll forming machine together, including the drawing, thickness of material, hardness of the steel coil, the input width of the steel coil, capacity of the roll forming machine.

We can help you to find the real manufacturer of steel coil manufacturer. Say bye to Trade company. So you can order the material coil with lowest price.

During production:

We can send the pictures to show you the schedule of your roll forming machines.

We will show you my blogger account for you to learn knowledge of roll forming machine if you would like

We will ask you what color of the roll forming machine body. Produce the machine under your suggestion

After-sale service:

We supply one year guarantee for the machine. The parts of the roll forming machine are free to send you and you only need to pay the cost of freight. And you can aslo solve it if you ordered more parts for your rol forming machine.

We supply all life tech support of our roll forming machines, Any questions, you can contact me by whatsapp.( I suggest that whatsapp or wechat is good. Because i can get your words timely) Important thing, you can write mail to me.

Standard Export packing:

1.one 40ft container for loading one set machine with manual decoiler;

2. the whole Wiped Anti Rust Oil, PLC controller covered by foam film;

3. Spare parts and some small parts packed in plastic tooling box;

4. All Components Fixed by steel wire with Container.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!