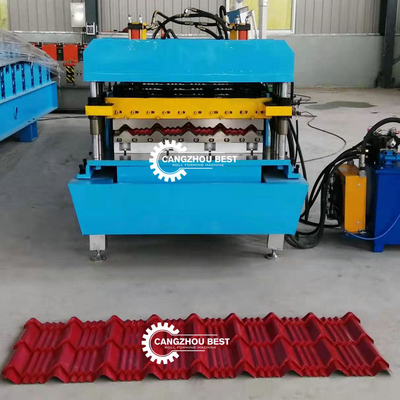

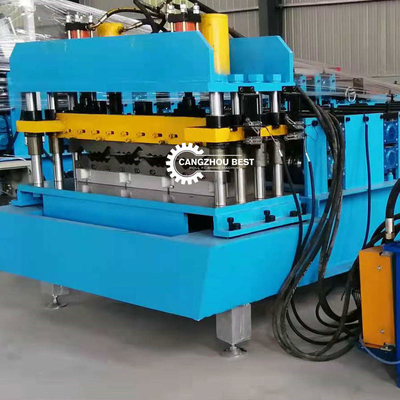

Kenya Popular Deep Rib PPGI Roofing Tile Forming Making Machine

1. Working Flow:

Decoiler--feeding materil--roll formng--pressing and cutting--output table

2. Technology Index

Cutting distance≥150mm

Temperature of the working environment of the production line: 0—40 Celsius

Humidity of the working environment of the production line: 5-85 (No dew)

Working Voltage: Three Phase Voltages 380V (AC)

Working Environment: No corrosive gases, less dust.

Error of Cutting Distance of Glazed Tile: ±1-2mm

The main description

Roll Forming Machine: CLASIC

Control System: PLC

Un-coiler:

UnCoiler : 5 ton manual

Decoiling Holder: 2200mm×1620mm×1700mm

inside diameter of the uncoiler: 510-610mm

Roll forming machine:

Color Steel Sheet Thickness: Color Sheet 0.3~0.8mm

Color Steel Sheet width: 1220mm

Roller Stations: about 16 stations

Way Of Drive: 1.2 inch single chain

The speed of the roll forming machine: 5-6m/min

Roller Material: 45# forge steel, coated with chrome

Shaft Material and DIA: 76mm, material is 45# forge steel

Maim Motor Power: 7.5kw

Error of Cutting Distance of Glazed Tile: ±1-2mm

Roll Forming Machine: 8700mm×1622mm×1400mm

Roll Forming Machine: 8000kg

Press parts

Type Hydraulic

Hydraulic Station Power: 5.5kw

Size of the press parts: 2000*1800*1500mm

Cutting parts

The cutting device is driven by hdyraulic station.The cutting device is driven by hdyraulic station. Meterial of the cutting:Cr12Mov with quenched treatment. It can decide cut panel dimension acoording to the hydraulic drive and Plc computer control system.

PLC control system

Panasonic PLC is adopted to organize all actions of the machine. The length of workpiece is adjustable according to the setting of on the PLC. Two optional control modes: automatic and manual. By automatic mode, the machine can realize fully automatic working.

In order to make the machine has a long service life and easy maintenance; we only adopt globally famous electrical components.And by our special designed program, the human-computer interface is very easy to be adopted by any level of operators

Passive Out table

Size of the out table: 2000*1350*1000mm, two pieces

3. Technical Parameters

| Technical Parameters (some depend on the final design) |

| 1 |

Style |

Bolivia glazed roof tile double layer roof sheet roll forming machine |

| 2 |

Machine dimension |

7500*1600*1650mm |

| 3 |

Total wight |

5800kgs |

| 4 |

Forming steps |

11rows |

| 5 |

Forming speed |

Glazed design :1.5-3.0m/min |

| 6 |

Hydraulic station power(Kw) |

4kw |

| 7 |

Diameter of shaft |

70mm |

| 8 |

Hydraulic pressure |

18-20 MPa |

| 9 |

Electric condition(Voltage ) |

380V/3Phase/ 50HZ (or based on customer's need ,for example :220V 440V 415V or 2Phase 60HZ ) |

| 10 |

Suitable to process |

Color steel plate(G330 or G350 ) galvanized steel coil |

| 11 |

Manual uncoiler max capacity |

5000kgs |

| 12 |

Control system |

PLC |

| 13 |

Raw material thickness |

0.3-0.8mm |

| 14 |

Effective width |

800mm and 836mm |

| 15 |

Material width |

1000mm and 1000mm |

| 16 |

Main motor |

3Kw |

| 17 |

Material of the cutting blade |

Cr 12 quenched treatment 58℃-62℃ |

| 18 |

Main Shaft Material

|

45# steel with finish turning |

| 19 |

Roller materials |

45# Forging Steel with Chromium Plate |

| 20 |

Machine Under Frame |

400 H beams and side wall 18mm |

2.Components of glazed roof tile double layer roof sheet roll forming machine

| 1 |

Manual uncoiler |

1 set |

| 2 |

Sheet guiding equipment |

1 set |

| 3 |

Roll forming system |

1 set |

| 4 |

Pressing device |

1 set |

| 5 |

Post-cutting equipment |

1 set |

| 6 |

Hydraulic station |

1 set |

| 7 |

Electric controlling system |

1 set |

| 8 |

Support table |

2 pieces |

4. Our service:

| 1. Installation and training: |

|

A. If buyers visit our factory and check the machine, we will teach you how to install and use the machine,

and also trainyour workers/technician face to face.

|

| B. Without visiting, we will send you user manual and video to teach you to install and operate. |

|

C. If buyer needs our technician to go to your local factory, please arrange board and lodging and

other necessary things.

|

| 2. after Service |

| 18 month, and we will provide technical support for wholelife of the equipment. If some parts of machine broken within 18 month, we will give customer the spare parts for free. (include chain, bearing, roller,oil pipe, counting wheel) If more than 18 month, maybe some spare parts need to be charged. If machine can not work well, we can teach them online until the machine is perfect. If you need, we can go to your place to assist you. But you need to provide the cost of the engineer. |

5. Packing:

Before loading to container, we will check the machine first. Second, make some protection on the machine. Such as, we will make the plastic package on the easy damage parts, paint the oil on the roller and shaft, in case the roller and shaft gor corrosion and rusty during long time delivery.

Third, we will fix all the parts into container by the steel wire rope. And ensure the glazed tile roofing sheet roll forming machine will not damage when shaking on sea.

At last, we will take photos and videos for customer when loading to container, so that the customer can take out the machine easily when receive the goods.

6. Machine photos:

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!