Product Description:

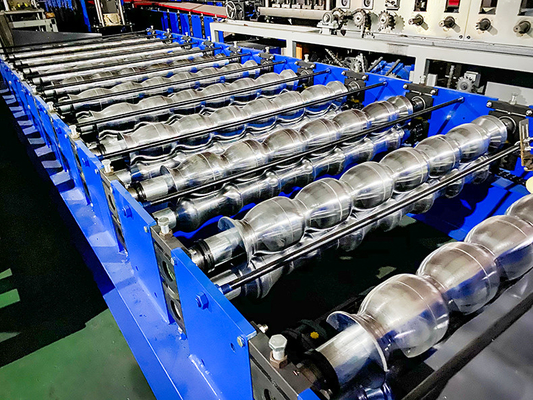

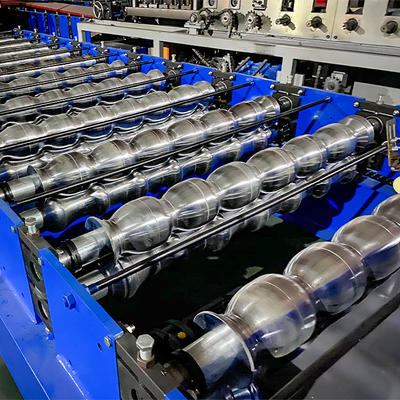

One of the standout features of this tile machine is its chain transmission, which ensures that the machine operates smoothly and efficiently, reducing the likelihood of breakdowns or downtime. This makes it an ideal machine for those who need to produce tiles on a consistent basis.

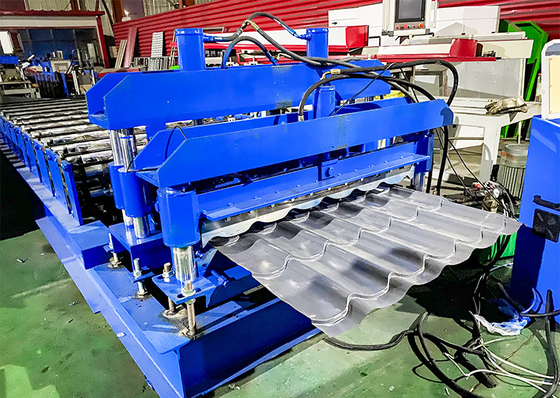

The Roof Tile Roll Forming Machine also features hydraulic cutting, which allows for precise and accurate cuts to be made quickly and easily. This feature is essential when working with tiles, as any mistakes can be costly and time-consuming to fix.

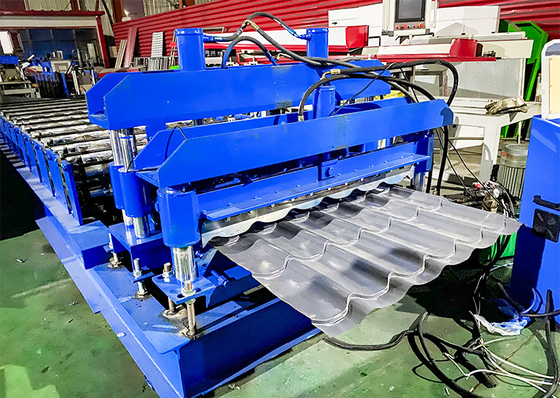

The size of the machine is also worth mentioning, as it measures 9.5*1.2*1.5m, making it compact enough to fit into most workshops or factories without taking up too much space. This is an important consideration for those who may be working with limited space.

All in all, the Roof Tile Roll Forming Machine is a reliable and efficient roof machine that is perfect for those looking to create the imitation of tiles for their roofing needs. With its powerful motor, high productivity, chain transmission, hydraulic cutting, and compact size, this machine is a great investment for anyone looking to improve their tile production process.

Features:

- Product Name: Roof Tile Roll Forming Machine

- Productivity: 4m/min

- Roller Material: 45# Steel

- Roller: 18 Rows

- Width of Material: 1200mm

- Transmission: Chain Transmission

- Features: The Roof Tile Roll Forming Machine is a high productivity machine that can produce 4 meters of the imitation of tiles per minute. It has 18 rows of rollers made of 45# steel and can accommodate material up to 1200mm in width. The machine is equipped with a chain transmission system.

Technical Parameters:

| Material |

Aluminum, Steel, Etc. |

| Productivity |

4m/min |

| Roller Material |

45# Steel |

| Cutting Blade |

Cr12 |

| Machine Frame |

300H Steel |

| Cutting Type |

Hydraulic Cutting |

| Weight |

6.5T |

| Thickness of Material |

0.3-0.8mm |

| Control System |

PLC Control System |

| Transmission |

Chain Transmission |

This table shows the technical parameters of the Roof Tile Roll Forming Machine. It is suitable for producing glazed tile with a production speed of 4m/min. The roller material is made of 45# Steel and the cutting blade is Cr12. The machine frame is made of 350H Steel and it uses hydraulic cutting. It weighs 6.5T and can handle materials with a thickness of 0.3-0.8mm. The control system is a PLC Control System and it uses Chain Transmission for transmission.

Applications:

The glazed metal roof produced by this machine is suitable for a wide range of applications. One of the most common uses is for roofing on residential buildings. The steel glazed tiles are strong, durable, and provide excellent protection against the elements. This makes them an ideal choice for areas that experience harsh weather conditions such as heavy rain or snowfall.

The imitation of tiles produced by this machine is also perfect for commercial buildings. The glazed metal roof is easy to install and requires minimal maintenance, making it a cost-effective choice for businesses. Additionally, the steel glazed tiles can be customized to match the style and color scheme of the building, which adds to the aesthetic appeal of the structure.

Another application of this tile machine is for industrial buildings. The strong and durable steel glazed tiles provide excellent protection for factories, warehouses, and other industrial structures. The tiles are also resistant to fire and can help prevent the spread of flames in the event of a fire.

In summary, the Op Sale Glazed metal roof Metcopo Tile Roll Forming Machine Building Material Machinery is a versatile and reliable machine that can produce steel glazed tiles for a variety of applications. With a width of material of 1200mm and hydraulic cutting type, it can produce high-quality tiles to meet the needs of various customers. Whether you are building a residential, commercial, or industrial structure, this tile machine is an excellent choice that will provide long-lasting protection and aesthetic appeal.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!